Brantz von Mayer and The Writers for Hire

Overview

When you consider the physical support systems for modern living, you may think of roads, electricity, computers, or even advances in farming and agriculture. Dredging is rarely on people’s list of life-changing technologies. Yet, without dredging, supply lines for hundreds of thousands of products would be shut down. Many of our ports and waterways would quickly become untraversable, and much of the recreation and tourism made possible by our seashores, lakes, and rivers would slowly diminish and finally cease as beaches eroded, lakes filled in, and rivers changed course. The construction industry would be severely hampered by lack of inexpensive sand and gravel, and many civil works projects – including important bridges and reservoirs – would be impossible.

In this overview of dredgers and dredging, we provide a brief summary of the how, what, and why of twenty-first century dredging: what is it, how does it work, and why is it so imperative to the day-to-day survival of modern society.

What is a Dredger?

A dredger (or “dredge” as is the general usage in the Americas) is any device, machine, or vessel that is used to excavate and remove material from the bottom of a body of water. For example, a scoop attached to the end of a rope or pole by which a man can draw sediments up from the bottom of a pond is a dredger. Developing this idea further, a motorized crane equipped with a drag bucket or clamshell (grabber) that is used to scoop material from the bottom of a body of water is also a dredger. The crane could be located on the bank, or perhaps mounted on a barge. If the crane is mounted on a barge, the entire vessel is referred to as a dredger.

Another type of dredger uses moving water to suction up the material to be dredged and transport it in suspension through a pipeline. This type of dredger most commonly uses a pump to suck up the material from the bottom and pump it to a remote location, however, other means can be used to impart motion to the water, such as air lifts or siphons.

Why Dredge?

We live on a dynamic and constantly changing planet. Left to nature, rivers flood and change course, lakes fill in, and coastlines change. We humans, however, want our lakes, rivers and beaches to stay put so that we can enjoy the aesthetic, recreational, and economic benefits that they provide. By the responsible use of dredging, we can prolong the life of lakes, make rivers behave, and replace eroded beaches. We can restore, improve or even create new habitats for marine and coastal animals and plants.

By the use of dredging, we can improve natural harbors, or create harbors where none existed before. By extending and improving existing waterways, we can extend the benefits of waterborne commerce far inland. We use dredgers to prepare the underwater terrain for civil works such as dams, and bridges, and to create spillways, levies and other marine works. Dredging also provides us with an economical source of sand and gravels for use as aggregates in cement and for use as road bedding. Since most of the visible evidence of dredging is submerged underwater, it is easy to overlook the critical role that dredging plays in our daily lives; but without dredging it would be impossible to maintain our modern way of life.

Types of Dredgers

There is a very large variety of machines and vessels that are designed for underwater excavation, but all dredgers can be classified into three main categories:

Mechanical, and hydraulic dredgers are characterized by the method that is used to excavate the material from the bottom of the body of water. Hopper and hold dredgers can use either mechanical or hydraulic means to excavate the material and are characterized by their ability to store the dredged material onboard for transportation.

Mechanical Dredgers

A mechanical dredger scoops up the material to be dredged by applying mechanical force to the material by means of an implement, such as a bucket or a grab. The dredged material is then lifted out of the water in the bucket or grab where it is usually deposited on some conveyance, such as a barge, for transportation to a designated disposal site.

Hydraulic Dredgers

A hydraulic dredger uses moving water to suction up the material from the bottom and transport the dredged material through a pipeline in the form of a slurry. Sometimes, when the material only has to be transported a very short distance, the pipeline is eliminated, and the material is projected alongside the dredger by means of a high pressure jet. Hydraulic dredgers are called such because the medium for elevating the dredged material from the bottom and transporting it to another location is moving water. The name is not, as is sometimes supposed, derived from the onboard pressured hydraulic oil systems that may operate the machine functions of the dredge itself.

The most common form of a hydraulic dredger has an onboard pump that sucks the material up through a tube that is lowered to the bottom of the body of water and pumps it through a pipeline to a different location. There are several other types of hydraulic dredgers which use alternative means of initiating water movement and creating the slurry, for example: airlift dredgers, jet lift dredgers, and pneumatic dredgers. Some resources classify these specialty dredgers in their own categories. However, because each of these dredgers use moving water as the end of elevating and transporting the material, they can all be considered hydraulic dredgers.

Hopper and Hold Dredgers

Hopper and hold dredgers are characterized by their ability to deposit dredged materials into onboard holds for transportation to a remote dump site. As the name implies, hopper dredgers have more or less funnel shaped holds that incorporate the ability to dump the material out through the bottom of the hold. Hold dredgers have rectangular shaped holds with no provision for bottom dumping. This type of dredger must be unloaded by some other means, such as an onboard or shore based clamshell crane, or a conveyor system.

Hold dredgers have larger holds than hopper dredgers do because of their square shape, but the tradeoff is that they must be unloaded by a crane, conveyor or pump out system, where a hopper dredger can simply open her bottom and let the cargo dump out. Hopper dredgers must float while their bottoms are open to the water, so a lot of room that might be used for cargo must be used for floatation chambers instead. Consequently they have smaller holds than hold dredgers, but they are able to discharge very quickly. In practice, hold dredgers are commonly specialized for winning and transporting sand to some dockside facility, and are often referred to as “sand carriers”. Hopper dredgers are commonly used for such tasks as deepening and maintainig ship channels and other jobs where the cycle time between dredging and disposal is very important.

Hopper and hold dredgers cannot be neatly categorized as either hydraulic or mechanical, since they can use either mechanical or hydraulic means to load the hopper. When one thinks of hopper dredgers, trailing suction hopper dredgers may come to mind first. As the name implies, this type of dredger uses hydraulic means to load the hopper. However, loading the hopper with a clamshell crane or excavator is also common. Some hopper dredgers, such as those built specifically for harbor maintenance, are equipped with both hydraulic and mechanical dredging systems. Consequently, the only real distinguishing characteristic of hopper and hold dredgers is their ability to transport the dredged material onboard.

How Does Dredging Work?

Dredging can be broken down into four steps.

- Dislodging the material to be dredged from the bottom.

- Transporting the material from the bottom to the surface.

- Transporting the material to a disposal site.

- Disposing of the dredged material.

Dislodging The Dredged Material From The Bottom

Before material to be dredged can be transported to the surface, it must be dislodged from the bottom. Depending on the job parameters and the type of material to be dredged, the method of dislodging the material varies. In the case of hydraulic dredging, the material at least requires agitation, if not excavation, to detach it from the bottom so that it can be drawn into the suction mouth. Mechanical dredgers use an excavating implement to scoop the material up. In the case of solid rock, it is common to first use explosives or vibratory hammers to fracture the rock preparatory to dredging, but some large dredgers have the capability of excavating the rock directly. The system used for dislodging the material from the bottom is usually integral to the design, and dictated by the purpose of the dredge.

- Plain suction dredgers are useful only when the material to be dredged is very loose, such as fine sand or silt. This type of hydraulic dredger uses only suction to draw up the material, somewhat like the hose attachment of a household vacuum cleaner.

- Jet Suction Dredgers are similar to plain suction dredgers in the sense that they are hydraulic dredgers that do not use a mechanical implement to dislodge the material. Instead, high pressure water jets directed into the material in way of the suction to help to dislodge the material and put it in suspension so that it can be captured by the suction stream.

- Cutter Suction Dredgers are hydraulic dredgers that incorporate a rotating cutter at the end of the suction line. This implement is shaped sort of like a basket (hence the term basket cutter), and has several blades that rotate around its axis. As the blades contact the bottom, each blade scoops out a section of material, which is caught up in the stream of water that is being sucked up by the dredge pump. A variety of edges can be attached to the blades for efficient cutting in various materials. With the proper edges and enough horsepower, some large cutter suction dredgers can even cut unfractured rock.

- Bucket Wheel Dredgers are a variation of cutter suction dredgers, except that the basket cutter is replaced with a narrow rotating drum with toothed buckets around the periphery. As each bucket takes a cut, the material is sucked into the drum and up the ladder.

- Horizontal cutter dredgers are hydraulic dredgers that use an auger that is covered by a shroud to convey the material being dredged to the suction mouth. The cutter actually consists of two counter-biased augers rotating on a single shaft that crowd the material towards the suction mouth. Sometimes the auger is replaced by a beater that agitates the material inside the containment of the shroud, where it can be captured by the suction stream. The beater is often augmented with teeth to increase the cutters effectiveness in harder materials. Horizontal cutter dredgers are very efficient at dredging fairly soft sediments but are not useful in harder materials.

- Dustpan dredgers are a type of hydraulic dredger that uses a wide flattened suction mouth that has a multitude of high pressure water jets attached to the bottom lip. As the cutter is pushed or pulled along the bottom, the water jets are directed into the material to be dredged, and the force of the water stream dislodges and suspends the material so that it can be captured by the suction stream of the dredge pump.

- Excavator dredgers are a type of mechanical dredger that uses a tooth-edged bucket attached to an articulated arm that is used to scoop up the material and elevate it to the surface. Some excavator dredgers can exert very high cutting force to the material being dredged; the larger dredgers are even capable of excavating unfractured rock.

- Dragline dredgers are mechanical dredgers that use a tooth-edged bucket shaped like a rectangular box with the top and one end open. The bucket is suspended from a crane by a wire rope called the hoist rope, and also connected to the crane on its forward edge by another wire rope called the drag rope. The bucket is lowered to the bottom and dragged across the bottom (towards the dredger) with the drag rope. As the bucket is dragged across the bottom, its leading edge engages the bottom and scoops material into the bucket. When the bucket is full, it is lifted out of the water with the hoist rope, while keeping tension on the drag rope to keep the bucket level. The crane then typically performs a swing operation to position the bucket over the place where the material is to be deposited. The tension on the drag rope is then released, causing the bucket to “trip” and dump its load.

- Clamshell dredgers are a type of mechanical dredger that uses a bivalve grab suspended from a crane that can be opened or closed by means of a cable or by hydraulic cylinders. The grab is lowered to the bottom in its opened position and then closed, essentially taking a bite out of the bottom. The grab is then hauled to the surface and a swing operation is typically performed to position the grab over the place where the material is to be dumped. The grab is then opened and the material released, and another swing operation is performed to position the cutter over the dredging cut. Finally the bucket is lowered once again to the bottom and the cycle begins again. A clamshell type grab can also be fitted to an excavator, and this configuration is very useful for certain environmental cleanup projects because of the high degree of depth and position control afforded by the excavator. Specially designed clamshells, called environmental clamshells, are designed to minimize turbidity when closing, and seal tightly when closed, thereby minimizing the release of the contaminated sediment into the water column when the clamshell closed and raised from the bottom.

- Bucket Ladder Dredgers use a series of buckets attached to a transmission chain, the chain riding on a boom or “ladder” that can be lowered to the bottom. Each bucket takes a scoop out of the bottom and is hauled up the ladder by the transmission chain. When the buckets reach the top of the ladder they invert, dumping their cargo onto a conveyor before beginning their journey to the bottom for another scoop.

Transporting The Material From The Bottom To The Surface

Once the sediment has been separated from the bottom, it starts its journey to the surface of the water. The two methods of transporting sediment are:

- Sucking the material through a pipe in the form of a water/material slurry

- Physically hauling the dredged material to the surface using a bucket or other mechanical device.

With mechanical dredgers, the non-productive time spent lowering the dredging implement to the bottom and elevating the material to the surface increases with depth, thereby increasing the cycle time and lowering overall production.

Transporting The Material To A Disposal Site

Once the material reaches the surface, sediments are sometimes moved directly from the dredger to a disposal site by pumping them through a pipeline in the form of a slurry. Alternatively, sediments can be brought onboard a dredger or barge, contained, and then shipped to a disposal site. The cost of sediment transport and subsequent disposal can represent a high proportion of the overall dredging operation. 1

Disposing Of The Dredged Material

Most dredged material (often referred to as “dredge spoil”) is transported to a designated site and dumped as a byproduct. Some dredged material, such as contaminated soils, must be treated before they can be safely returned to the environment, or contained in specially sealed disposal sites. “Disposal,” however, can be a somewhat misleading term. In many cases sediments can be recycled for beach nourishment, land creation, or construction uses. In fact, sometimes the utilization of the dredge spoil for a commercial or environmental purpose is the principal objective of the dredging project.

The best use of dredged material often depends on the sediment type that the dredgers extract. The U.S. Army Corps of Engineers provides the following chart as a general guide to matching soil type to the most appropriate use for the dredged material 2:

| Dredged Material Sediment Type | |||||

| Beneficial Use Options | Rock | Gravel & Sand | Consolidated Clay | Silt/Soft Clay | Mixture |

| Engineered Uses | |||||

| Land creation | x | x | x | x | x |

| Land improvement | x | x | x | x | x |

| Berm creation | x | x | x | x | |

| Shore protection | x | x | x | ||

| Replacement fill | x | x | x | ||

| Beach nourishment | x | ||||

| Capping | x | x | x | ||

| Agricultural/Product Uses | |||||

| Construction materials | x | x | x | x | x |

| Aquiculture | x | x | x | ||

| Topsoil | x | x | |||

| Environmental Enhancements | |||||

| Wildlife habitats | x | x | x | x | x |

| Fisheries improvement | x | x | x | x | x |

| Wetland restoration | x | x | |||

Table 1 – U.S. Army Corps of Engineers: http://el.erdc.usace.army.mil/warning.cfm

Dredging Applications

Dredging can be divided into five major general categories:

- Capital Dredging

- Maintenance Dredging

- Dredging for Civil Works and Energy

- Mining

- Environmental Dredging

Capital Dredging

Capital dredging is a dredging project in which the purpose of the project is to substantially change the underwater or shoreline terrain for a commercial purpose.

Capital dredging for ports and harbors

Harbors and ports naturally create a thriving populace. In fact, eight out of the ten largest cities in the world are located along the coast. Capital dredging provides new or improved waterways for navigation, harbors for berthing of ships or boats, and canals for water management, and flood control. 3

In the past, mankind had to rely on natural harbors and waterways to provide safe refuge and berthing for ships carrying the goods of commerce. But very early on, man was seeking to create new waterways. As early as 1897 BC, early Egyptians attempted to join the River Nile and Red Sea to improve navigation. 4

Today, the Panama Canal, Suez Canal, and many other important waterways could never have been built without dredging. By dredging, rivers are deepened and widened so that waterborne traffic can extend far into the interior of the land, and completely new waterways are created.

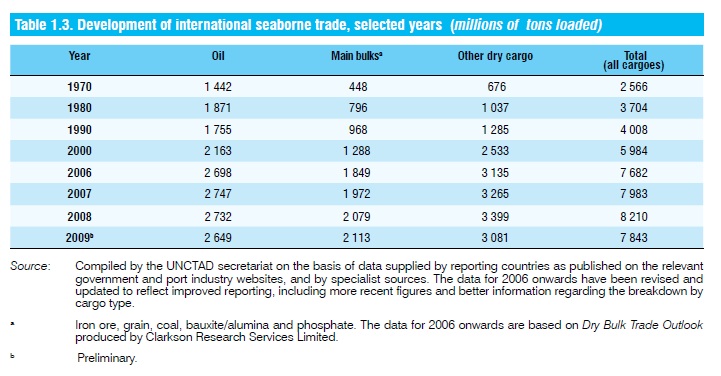

Yet creating waterways is only half the battle. Shipping traffic increases steadily with global trade and ships grow larger to meet the growing need for international goods. In response to the growing size and number of ships, dredgers must constantly work to improve and deepen existing ports and canals. According to the United Nations Conference on Trade and Development, from 1970 to 2009, sea borne trade increased over 5 million tons: 5

(Reprinted from the following United Nations Publication: UNCTAD/RMT/2010)

Examples of well-known dredging projects that have made modern marine commerce possible include:

- Suez Canal. This manmade waterway connecting the Mediterranean and Red Seas is one of the most well-known dredging accomplishments in the world. Although men attempted to create this passageway as early as 1897 BC, it wasn’t until almost 4,000 years later that dredging technology was advanced enough to finally complete this much anticipated “Highway to India.” 6

- Deepening the Suez Canal was also a major accomplishment. Originally the canal was just 25 feet deep. Today the canal maintains an entire fleet of dredgers – not only to keep the waterway from being reclaimed by the surrounding land, but to continually deepen the waterway to accommodate ever-larger ships.

- Port of Tanjung Pelepas. Malaysia’s largest port is a notable case study in fast-track dredging and development. It received its maiden vessel in October of 1999 and was declared the world’s 16th busiest container port by 2004. 7

- Panama Canal. The Panama Canal – the 80-kilometer artificial waterway joining the Atlantic and Pacific Oceans – has been dubbed one of the Seven Wonders of the Modern World by the American Society of Civil Engineers. Completed in 1914, the engineering project was the largest of its time. During initial construction, dredgers, excavators, and workers moved enough earth to open a 16-foot-wide tunnel to the center of the Earth. 8

Capital dredging for land reclamation

The material that is dredged up is not always simply disposed of, but is often used for some beneficial use. This concept is not new. Major residential portions of San Francisco, Galveston, and Portland have been built on the “leftover dirt” from capital dredging projects. 9 Dredged material has also been used to create land for recreation, farming, industrial use, civil projects, and even forestry.

More and more these days, dredged material is considered the desired product, and the water deepening a byproduct. There are many major capital dredging projects which involve creation of land for its own sake, including: the Kingsford Smith Airport in Sydney, Brisbane International Airport, New Doha Airport, land improvements in Guayaquil Ecuador, and the Oresund and Storebaelt (Great Belt) Fixed Links. 10

More famous examples of dredging projects involving land reclamation include:

- Hong Kong International Airport. After just 12 years of operation, by 2010, the Hong Kong International Airport ranked the world’s busiest airport by cargo traffic. 11 Yet because large tracts of land are so scarce in Hong Kong, this well-known airport may never have been possible without modern dredging. The airport is built on 2,300 acres of new land – land that didn’t exist before the early 1990s. 12 The new airport increased Hong Kong’s land mass by nearly 1% and was listed as the world’s most expensive airport by Guinness World Records. 13

- Singapore, Jurong and Tuas Expansions. In Singapore, seven islands have become one. To satisfy its need for more industrial land, Singapore needed to get creative. In its southwest corner, Singapore used dredging to link seven nearby islands to Jurong and expand the Tuas Peninsula. 14

- Palm and World Islands of Dubai. In 2011, the work underway in the Persian Gulf represented the world’s largest land reclamation project: three islands in the shape of palms, 12,000 private homes, hotels, and restaurants, 300 tiny islands shaping a map of the world, and hundreds of miles of brand new coastline. 15 The three Palm Islands will be the largest manmade islands on earth, and they have already been declared the eighth wonder of the world. 16

Maintenance Dredging

Maintenance dredging is a dredging project that does not substantially alter the underwater or shoreline terrain, but maintains a body of water in a certain desired condition.

Can anyone imagine New Orleans without the Mississippi River? It is a real possibility. The Mississippi River, wants to divert into the Atchafalaya basin, and it is only due to year-round maintenance of the existing channel, together with an extensive system of levies, spillways and locks that the river is kept on its present course. Dredgers are constantly working to keep that course static. It’s not an easy task.

Just to maintain navigable waterways, approximately 300 million cubic yards of material – enough to fill about 3 million backyard swimming pools – are dredged in the USA alone each year. 17

It is entirely natural for river beds fill in, causing rivers to overflow their banks in search of a new channel. Left to nature, most rivers change course from time to time. 18 Rivers carry:

- Natural minerals (from erosion)

- Seabed materials (swept up into the lower courses via tidal action)

- And organic matter (from decaying plant and animal material)

Together these suspended particles are referred to as sediment. Where the river flows quickly, the particles remain suspended, but in places where the river slows down, the sediment precipitates out of the water and falls to the bottom, filling in the channel, and causing the river to jump its banks in search of a new channel. Rivers also deposit sediment into the bodies of water they empty into, such as ports, bays, lakes, or oceans.

The toll in human suffering can be very high if waterways are not carefully managed. If river channels and levee systems are not constantly maintained, communities, towns, and farmland can be flooded, causing immense property damage and destroying the livelihood of the residents. Local and even global commerce can also be affected if the channels are not maintained. In 2004, over 200 million tons of cargo were shipped via the Mississippi — that’s the equivalent of one truckload, every 3 seconds, 24 hours a day, 365 days a year. 19 One can only imagine the global impact if the Mississippi became impassable.

Dredging is pivotal to maintaining manmade waterways such as the Panama Canal. In several places in the Panama Canal, the angle of repose – the angle of the bank at which landslides will not occur – has never been optimal. 20 A full fleet of dredgers is maintained by the Panama Canal to continually remove material caused by landslides, as well as perform ongoing upkeep to other sections of the canal.

Furthermore, constant maintenance dredging is needed for less obvious jobs which nevertheless play key roles in maintaining our way of life. For example, consider reservoir dredging. The life span of reservoirs is limited, because the water from the river that feeds them slows down at the reservoir, allowing the river sediments to precipitate out into the reservoir. This causes the reservoir to gradually fill in, reducing the amount of water it can hold for producing hydroelectric power or for irrigation, until finally the dam has to be abandoned. Dredging can remove the accumulated sediments and, to a certain extent, restore the volumetric capacity of the reservoir. Although dredging does not maintain reservoirs indefinitely (many reservoirs are so deep that restoring the original depth is often not economically feasible), dredging reservoirs can significantly lengthen the life of the reservoir thus prolonging the benefit of the investment.

Civil Works, Leisure, and Energy Projects

Dredging is essential to many civil works, engineering, and energy projects that are vital to our cities’ infrastructures. Dredging is needed to excavate land for breakwaters, dams, bridges, piers, docks, dikes, and wharves. The process for these underwater engineering projects is similar to their land counterparts. For example underwater trenches are created and filled to receive pipelines, power cables or communications cables and sea beds are prepared for foundations to support bridges or dams.

One example of a massive civil works project is the creation of the 1800-meter dam that encloses Saldanha Bay in South Africa. This bay is South Africa’s largest natural anchorage and deepest port, but it only recently became a modern harbor. Prior to the improvements, the port facilities were open to attacks from the ocean’s waves – many reaching 12 meters high in the area. To protect the port, a dam between Marcus Island and Hoedjes Point was necessary. However, each time sediment was deposited, the ocean current immediately dispersed it. It eventually required the coordination of four dredging contractors to deposit sediment fast enough to lay down the 20 million cubic meters of sand necessary for the dam. 21

Leisure, parks, and tourism

The idea that dredging can be used to increase tourism is not new. As early as 1904, the Detroit Dredging Company was digging paddleboat lagoons for Cedar Park – the 364-acre Ohio theme park known for having more rides than any other amusement park. 22 More recently, dredging makes possible many 21st Century tourist attractions. For example, huge cruise ships such as the Royal Caribbean’s Oasis of the Seas –which houses 16 decks, a 3D movie theater, seven “onboard neighborhoods,” and 2,700 staterooms 23 – require oversized harbors to berth. 24 Such harbors are often only made possible with dredging. Dredging also allows tourism to come to remote areas, by making harbors and rivers passable to large tourist vessels.

Sometimes, the creation of waterside leisure facilities is coupled with other dredging projects. For example, leftover dredged material often creates land for new parks in urban areas, where harbors are frequently re-dredged. According to the U.S. Army Corps of Engineers, “recreation on dredged material containment sites is one of the most common land uses of dredged material sites, in actual acres.” The land created by fine-grained dredged material is especially suited to the lightweight park structures. 25

Energy projects

According to the International Association of Dredging Companies, energy-related dredging accounted for approximately 18% of the dredging market in 2009. 26 In the offshore oil industry, dredgers dig trenches for pipelines, prepare the seabed, and protect the pipelines by backfilling with gravel, sand, and rock. 27

Modern dredging has allowed us to drill deeper and in harsher conditions than ever before, which has greatly benefited the energy industry:

- Deep ocean drilling. According to Dredging in Coastal Waters, “the maximum depth of dredging the sea floor was reached off the Canadian east coast where offshore oil installations were placed in an excavation at 120 – 130 meter water depth.” 28 That means specialized offshore dredgers are now able to excavate deeper than the length of a standard American football field.

- Drilling in harsh conditions. Drilling in harsh arctic conditions such as those of the Beaufort Sea has only been possible because of modern dredging. In the Beaufort Sea, highly modified dredgers created artificial exploration islands necessary for the drilling operation. These dredgers had to be heavily specialized to transport the sand fill over frozen sea without being crushed by the thick layers of floating ice. 29

In addition to traditional oil and gas endeavors, new types of offshore energy solutions often require dredging. For example, the new underwater gas facility in the Philippines – the foundation of which was poured ½ mile below sea level 30 – would not have been possible without modern dredging. And dredges were vital in providing erosion protection and installing the turbines for the 80-turbine Horns Rev Offshore Wind Farm in Denmark. 31

Finally, dredging is also used in niche energy applications, such as fly ash dredging. Power plants often store their fly ash – a natural byproduct of combustion – in wet ash ponds. These ponds are created and maintained by dredging. Recently, fly ash dredgers have also been used to remove fly ash for resale. In a successful case study by Ellicott Dredges, a Baltimore based dredger manufacturer, a cutterhead dredge was able to remove 100% of the fly ash from a power plant ash pond; the ash could then be resold as fill material in highway construction. 32

Mining

In mining dredging, the sediment itself is the desired commercial product. Dredging provides a large part of the sand and gravel that is used as aggregate for cement, or for road bedding and other construction uses. Minerals such as gold and precious gems are also mined by dredging. Mineral mining dredgers are typically highly specialized, customized, and owned by the mining company themselves.

- Gold, useful minerals, and precious materials. In ocean mining, the dredger excavates the material, sorts and collects it, and disposes of any undesired sediments. Dredgers have been used to remove a long list of useful materials from the ocean floor:

- tin ore

- coal

- gold

- platinum

- silica

- titanium

- barite

- phosphates

- rare earth metals

- metalliferous oxides and sulfides

- aragonite

Dredgers have even used to mine diamonds off the coast of South Africa. 33 In the future, dredging may be used in seabed mining to recover natural metal ore nodules from the sea’s abyssal plains. 34

- Construction materials. Sand and gravel can be mined for use in construction, principally for concrete. The United Kingdom – the largest marine-aggregate dredging industry in the world 35 – excavates many 20 millions of tons of sand and gravel each year. This amount accounts for 19% of sand and gravel sales in England and 46% in Wales. 36

Environmental

Environmental dredging can be used to correct an adverse environmental impact, or it can create new environments and habitats where none existed before. Environmental dredging projects are often combined with, or are a natural byproduct of, capital dredging projects. For example, projects that deepen channels for navigation are often combined with flood prevention projects, as the deepened channel will naturally hold more water and reduce the amount of flooding in the surrounding areas. (Restoration of wetlands using dredged sediment can also reduce flooding, as just one acre of wetlands can store 1 to 1.5 million gallons of floodwater. 37)

Anti-eutrophication – or removal of sediments that have choked off oxygen supply to water bodies and stunted wildlife proliferation 38 – can also be a natural byproduct of dredging in a body of water.

Also becoming more commonplace is the reuse of sediments acquired from maintenance dredging (versus simply disposing of the sediments as waste). The California State Coastal Conservancy and U.S. Army Corps of Engineers have developed a 20-year plan to restore and expand the Hamilton Wetlands by the San Francisco Bay. 39 By the end of the project, approximately 1,600 acres of new wetlands will be created. To create the wetlands, the Corps will use the sediment from deepening and maintaining the Port of Oakland and other waterways in and around the San Francisco Bay.

The U.S. Army Corps of Engineers typically dredges about seven million cubic yards of sediment annually from the San Francisco Bay area. 40 In the past, this sediment was considered waste, and was disposed of at dumping grounds within the Bay; the waste quickly filled up the dumping grounds, causing a serious issue. In fact, the early 1990s plan to deepen Oakland Harbor was halted specifically because there was no available dumping ground for the sediment. 41 While the dredging sediment was piling up, the Hamilton Wetlands – an important breeding ground for thousands of animal and plant species – were losing sediment at an alarming rate. The San Francisco Bay has lost over 85 percent of its wetlands since the 1880s. 42 The solution was realized in around the turn of the millennium: dredged sediments could be used to replenish the wetlands. This solution not only promotes improved waterways in the area, but it has saved the Hamilton Wetlands Restoration project over $25 million in costs. 43

The State of Louisiana has also implemented a program to restore their wetlands using dredged sediment. In Louisiana’s case, maintaining the Mississippi River levees has inadvertently caused rapid erosion of Louisiana’s wetlands (nearly 25 to 35 square miles each year). The levees are necessary to keep the Mississippi on course, but they also cut off the supply of sediments that the wetlands needs to survive. Louisiana is now manually depositing sediment into their wetlands from nearby dredging projects. The Mississippi River Sediment Delivery System is expected to restore 500 acres of marsh to Louisiana. The State hopes to increase the amount of sediment it uses to restore its wetlands. Annually, the U.S. Army Corps of Engineers dredges about 60 million cubic yards of sediment from Louisiana’s waterways. If all of that could be used to restore coastal areas, it would cut land loss in Louisiana by almost two-thirds. 44

- Removing contaminated sediment. In areas of heavy industrial activity, contaminated sediments often accumulate in harbors, rivers, and coastal areas. Dredgers can remove these sediments and reclaim the area for the environment, tourism, or clean human habitation. For example, consider the restoration of the Ria Aviles in Spain. After several decades of winding between steel and coke factories, power plants, and 90,000 residents, the river had basically degraded into an open sewer. Recent removal of the contaminated sediment restored the river’s original beauty and greatly improved health conditions. 45

- Strip Mine Reclamation, Solid Waste Management, and Waste Removal. Dredgers are employed to cover landfills, refill old mining sites, and physically remove trash or debris from the bottom of rivers, canals, and harbors.

- Reestablishment of Water Flow. Dredging can renew needed fresh water flow in rivers that have been clogged by sediment. For example, in Bangladesh, the area surrounding the Gorai River – once a lush living environment – had become plagued with drought. Sediments deposited over several decades had caused much of the river to dry up, and the remaining flow to become overly salty. This situation had destroyed the nearby mangrove forest, and was making life unbearable for the residents. Dredgers removed the contaminated soil, which reestablished the fish population, decreased health risks, and enabled boating commerce to resume. 46

- Beach Nourishment. The creation of seawalls and other beach front construction has altered wave patterns along many of the world’s most visited shorelines. When a wave hits a structure, such as a seawall, the water is violently forced back out to sea, causing increased turbulence and increased erosion in the near shore zone. One solution is to use dredged material to create sand bars (or sand berms) several hundred yards offshore and parallel to the coastline. 47 Since 1988, this method of stabilizing beaches has been successfully on various shorelines, including Maresme Beaches, Victoria Beach in Cadiz, Alicante, Ischia, and Currumbin-Tugun Beach. 48

Consequences of Dredging

As much as dredging can have an impact for the good of mankind, it should be recognized that dredging operations also have the potential to detrimentally impact the environment. Unwise planning and improper equipment selection can introduce high turbidity into the water column to the detriment of the flora and fauna residing near the dredged area. Dredging can disturb toxic sediments that have remained dormant for years, creating an unwholesome environment for marine life, and the animals and humans that depend on the waterway for their livelihood. Dredging is often used to change the underwater landscape, but however beneficial the project might be, improperly planned dredging can have unexpected and undesirable impacts on water flow and natural sedimentation patterns.

The negative consequences of poorly planned dredging can include:

- Improper disposal of dredging sediment, which can cause disturbance to wildlife or human activities

- Improper disposal of contaminated sediment which can cause severe ecological impact

- Undesirable changes to river and ocean coastlines, which can result in destruction of habitat or increased flooding hazards

- Changes to currents or wave patterns which may reduce water quality or increase erosion or sedimentation in certain areas

Dredging also disturbs sediment in the short-term, which results in cloudy water and possibly the reintroduction of settled contaminants (such as heavy metals, DDT, and PCB) into the waterway. These contaminants can then end up in the food chain and eventually find their way into the human diet. An increase in turbidity can also interfere with fish spawning cycles. 49

Fortunately, we have learned from the mistakes of the past, and have developed means and methods of minimizing or eliminating the detrimental effects of dredging. The U.S. Clean Water Act mandates that all dredgers must first have an authorized permit for all discharge of dredged sediments into United States waters. Dredging in the U.S. is also restricted to licensed areas only, where vessel activity can be monitored with GPS systems. 50

By conducting careful environmental impact studies to predict the likely effects of a dredging project on the environment, and developing the proper tools and systems to ameliorate the negative impact on the environment, we can continue to benefit from the many advantages that dredging can provide while protecting or even improving the environment.

Resources and Citations

1. European Dredging Association: http://www.european-dredging.info/ab.html

2. U.S. Army Corps of Engineers: http://el.erdc.usace.army.mil/warning.cfm

3. International Association of Dredging Companies: http://www.iadc-dredging.com (About Dredging: Dredging in Figures, 2009)

4. Wikipedia Entry, Suez Canal: http://en.wikipedia.org/wiki/Suez_Canal

5. United Nations Conference on Trade and Development: http://www.unctad.org/en/docs/rmt2010_en.pdf. Document Number: UNCTAD/RMT/2010

6. Wikipedia Entry, Suez Canal: http://en.wikipedia.org/wiki/Suez_Canal

7. Wikipedia Entry, Port of Tanjung Palepas: http://en.wikipedia.org/wiki/Port_of_tanjung_pelepas

8. American Society of Civil Engineers: http://www.asce.org/content.aspx?id=2147487305

9. U.S. Army Corps of Engineers Education Center: http://education.usace.army.mil/navigation/dredging.html

10. International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=53&Itemid=77

11. Airports Council International and Centre for Asia Pacific Aviation: http://www.centreforaviation.com/news/2011/03/16/world-airport-rankings-2010-hong-kong-eclipses-memphis-as-the-worlds-busiest-cargo-hub/page1

12. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

13. Wikipedia Entry, Hong Kong International Airport: http://en.wikipedia.org/wiki/Hong_Kong_Airport

14. DEME: http://www.deme.be/projects/singapore_jurong2.html

15. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

16.International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=56&Itemid=80

17. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

18. Federal Ministry of Transport, Building, and Urban Affairs (Germany): http://www.dredging-in-germany.de/sites/englisch/englisch.html

19. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

20. Australian Crane and Machinery, Pty, Ltd.: http://mcaleese.com.au/acm/crane_history11a2.htm

21. International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=52&Itemid=76

22. Wikipedia Entry: Cedar Point: http://en.wikipedia.org/wiki/Cedar_Point

23. Royal Caribbean International: http://www.royalcaribbean.com/findacruise/ships/class/ship/home.do?shipCode=OA

24. Dredging indefinitely on hold, Royal Caribbean drops pledge. Constance Cooper: http://virginislandsdailynews.com/news/dredging-indefinitely-on-hold-royal-caribbean-drops-pledge-1.1043249#axzz1LgLHPwHN

25. U.S. Army Corps of Engineers Education Center: http://education.usace.army.mil/navigation/beneficial.html

26. International Association of Dredging Companies. Dredging in Figures – 2009. http://www.iadc-dredging.com/images/stories/dredging-in-figures/dredging-in-figures-2009-v2.pdf

27. International Association of Dredging Companies. Dredging in Figures – 2009. http://www.iadc-dredging.com/images/stories/dredging-in-figures/dredging-in-figures-2009-v2.pdf

28. Dredging in Coastal Waters, D. Eisma. http://books.google.com/books?id=iPDP4K0AnA4C&pg

29. International Association of Dredging Companies. http://www.iadc-dredging.com

30. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

31. International Association of Dredging Companies. http://www.iadc-dredging.com

32. Ellicott: Coal Burning Power Plant Uses Ellicott® Dredge to Produce Four Beneficial-Use Materials http://www.dredge.com/cwlp_pres_releas.html

33. Continental Margin Mineral Resources – Hard Minerals. https://geology.uprm.edu/Morelock/reshard.htm

34. New World Encyclopedia: http://www.newworldencyclopedia.org/entry/Dredging

35. European Dredging Association: http://www.european-dredging.info/ab2.html

36. British Marine Aggregate Producers Association: http://www.bmapa.org

37. Hamilton Wetland Restoration Project: http://www.hamiltonwetlands.org/faq.html

38. Hampton Roads Center for Civic Engagement: http://hamptonengages.com/learn/topics-of-study/waterway-dredging

39. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

40. Hamilton Wetland Restoration Project: http://www.hamiltonwetlands.org/faq.html

41. Cooperative Conservation America: http://www.cooperativeconservation.org/viewproject.asp?pid=334

42. Hamilton Wetland Restoration Project: http://www.hamiltonwetlands.org/index.php

43. Hamilton Wetland Restoration Project: http://www.hamiltonwetlands.org/faq.html

44. Environmental News Service. Louisiana Begins Wetland Repair with Mississippi River Sediment. http://www.ens-newswire.com/ens/apr2009/2009-04-14-093.asp

45. International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=55&Itemid=79

46. International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=55&Itemid=79

47. Modern Marvels, Season 11, Episode 38, Aired 8/3/05

48. International Association of Dredging Companies: http://www.iadc-dredging.com/index.php?option=com_content&task=view&id=56&Itemid=80

49. Wikipedia Entry, Dredging: http://en.wikipedia.org/wiki/Dredging

50. Wikipedia Entry, Dredging: http://en.wikipedia.org/wiki/Dredging